-

-

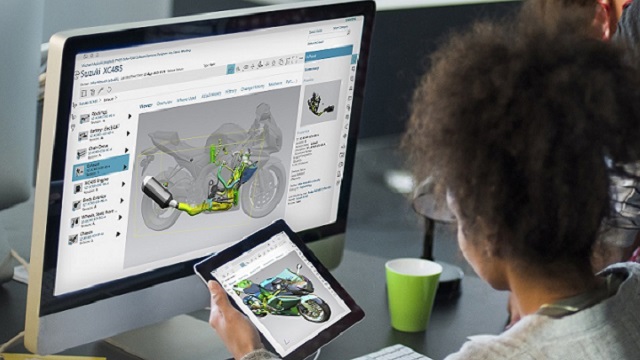

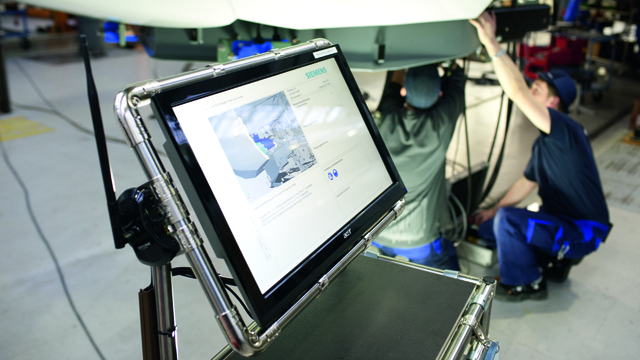

航空航天及国防行业

航空航天及国防企业正在以卓越性能为目标开发前沿的平台和系统。 政府针对全新的飞机和技术正大力推进基础设施和安全系统转型。 创新是其推动力,而在整个航空航天及国防产品生命周期和价值链中实施同步的协同式项目管理则可以促进创新。

-

-

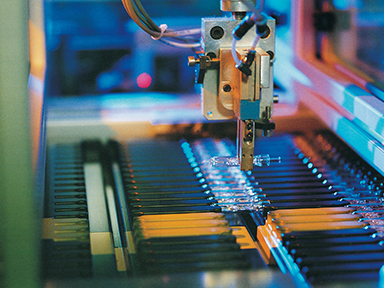

电子和半导体行业

电子和半导体企业需要基于行业典范做法的预配置软件解决方案来实现新产品开发和推广 (NPDI) 的卓越表现。 通过缩短创新和开发周期,实现整个供应链的协作,创建闭环、智能和集成的制造环境

-

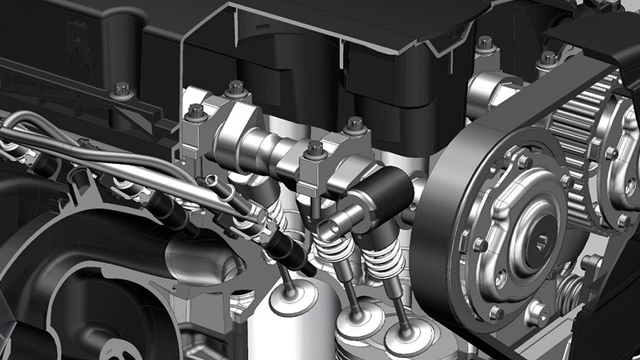

工业机械和重型装备工业

重型装备与工业机械已经具备了前所未有的复杂性。 在竞争日益激烈的市场当中,各公司不但要确保不断创新,还要应对复杂性挑战。 Siemens PLM Software 能够助您打造出适当的产品,还能让产品满足需求。

-

-

-

- NX

- Polarion

- Teamcenter

- Simcenter

- Manufacturing Operations Center

- Tecnomatix

- MindSphere

- PLM Components

-

-

-

-

-

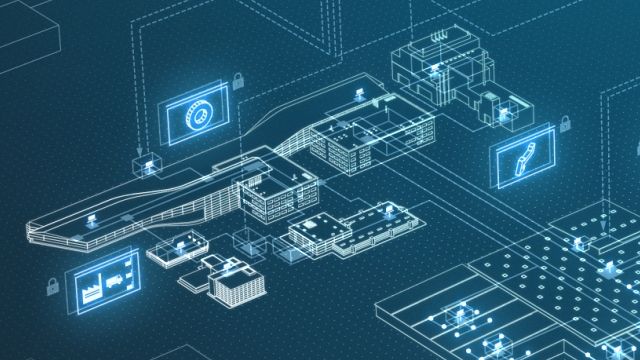

Siemens 制造运营管理 (MOM) 软件是一套完整的解决方案,用于实施有助于制造运营实现全面数字化的战略。

Manufacturing Operation Center

-

-

MindSphere

MindSphere is the cloud-based, open IoT operating system from Siemens that connects your products, plants, systems, and machines, enabling you to harness the wealth of data generated by the Internet of Things (IoT) with advanced analytics.

-

PLM Components

PLM Components are 3D software development toolkits that increase the value of CAD, CAM, CAE and related PLM applications by reducing the time, cost and risk of delivering 3D software innovation to your customers.

-

- Mechanical Design

- Electrical & Electronics

- Software Engineering

- Simulation & Test

- Manufacturing Planning

- Factory Automation

- Manufacturing Operations Center

- Performance

-

Simcenter

Siemens NX 软件是一款既灵活又功能强大的集成式解决方案,有助于您更快更高效地提供更优质的产品。 NX 提供了下一代的设计、仿真和制造解决方案,支持公司实现数字孪生的价值。

-

-

-

-

-

-

-

-

-

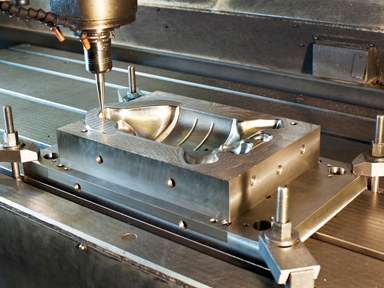

Additive Manufacturing Data and Process Management

|

Additive Manufacturing Data and Process Management

使用 Siemens 提供的数据管理解决方案获取整个增材制造流程中的数据。 这不仅包括与零件几何体相关联的数据,还包括涵盖整个构建托盘设置和打印参数的数据。 构建策略、后期处理和验证程序也是增材制造的部分难题。 要打造高质量、可重复的工业增材制造流程,正确管理此类数据十分关键。 借助 Siemens 提供的 Teamcenter,轻松、无缝地管理此类流程数据。 |

|

Manage the 3D printing process

Producing additive manufactured parts at an industrial scale, especially in metal, requires numerous manufacturing processes and post processes that must be managed. Setup and preparation of the printer as well as post-print steps such as substrate separation, heat treatment, finishing, and inspection are all steps that must be tightly controlled. |

|

|

|

Optimize material usage

Managing materials for the additive manufacturing process is another area where a tightly controlled process is mandatory. Counting the number of recycles and mixed powder batches is necessary for tracing the materials used in your printing operations. This traceability is important because you can't disassemble mixed powders and the amount of recycled powder used may affect the quality of the final print. |

|

Secure additive manufacturing data

Protect your organization intellectual property through robust data security measures. Siemens has partnered with Identify3D to integrate their suite of tools for protection of additive manufacturing data. The ecosystem provided by Siemens and Identify3D provides for a secure digital container to move and modify additive manufacturing data through the digital workflow. All of the necessary elements are integrated into the Siemens product set from NX CAD/CAM through to the machine controllers. |

|